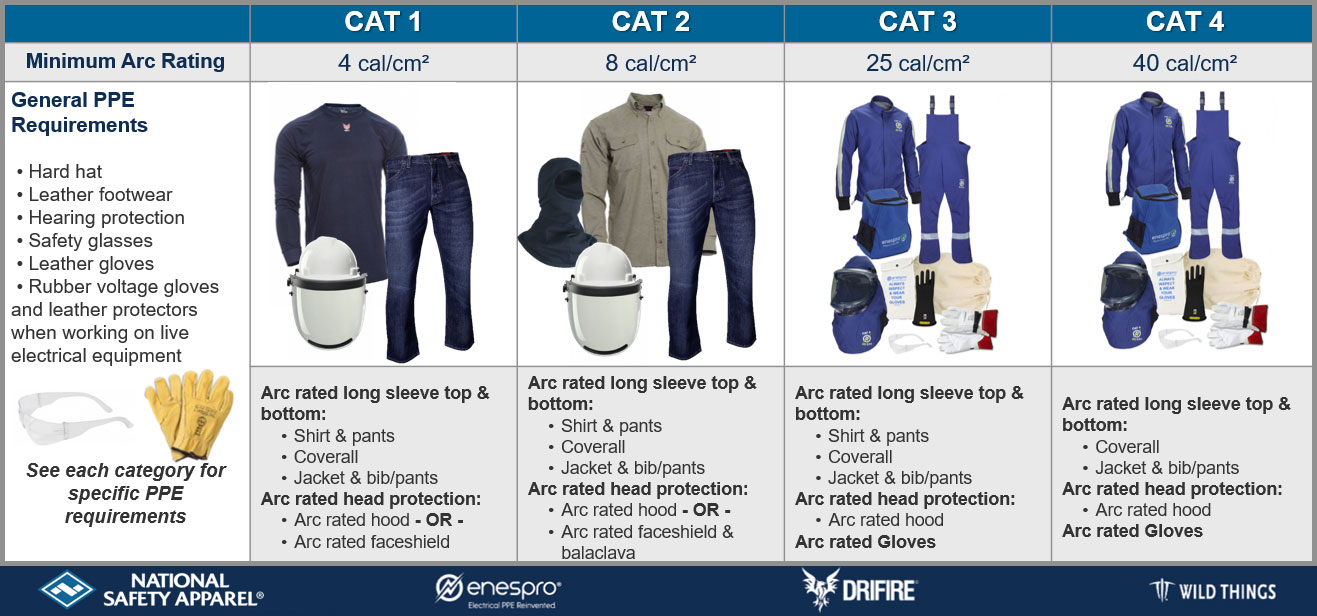

As safety professionals we all understand the imperative need for arc flash and electrical safety. This Arbill article is designed to provide you with vital insights into the world of arc flash and electrical safety. Here, we’ll discuss the dangers of arc flash incidents, the significance of training, arc flash protection equipment, risk assessments, and safety standards.

At Arbill, safety is our core value, and we are committed to providing you with the resources necessary to protect your team. In this article, we reference our range of products and solutions, giving you access to the best information without having to sift through data on competitive products.